Electronics Design

Whether you have a new circuit that needs to be designed or an existing one that must be updated we are here to help. A lot of our work revolves around updating legacy circuit designs. This is where we update a current design that is tried and true but with parts that are no longer available. This may require updating the micro controller and writing the new firmware to accommodate the existing circuit.

On the other hand when starting with a novel idea or new product we usually make proof-of-concept prototypes to demonstrate and test the functionality. Next, we design the required circuit as a platform that can be updated and programmed locally or wirelessly over the air as needed. The circuit will fit within the required space claim of the industrial design.

Below are the three steps we take from design to manufacturing when doing circuit design:

Circuit Architecture

First, we define a scope of work based on our client’s needs and the discovery phase.

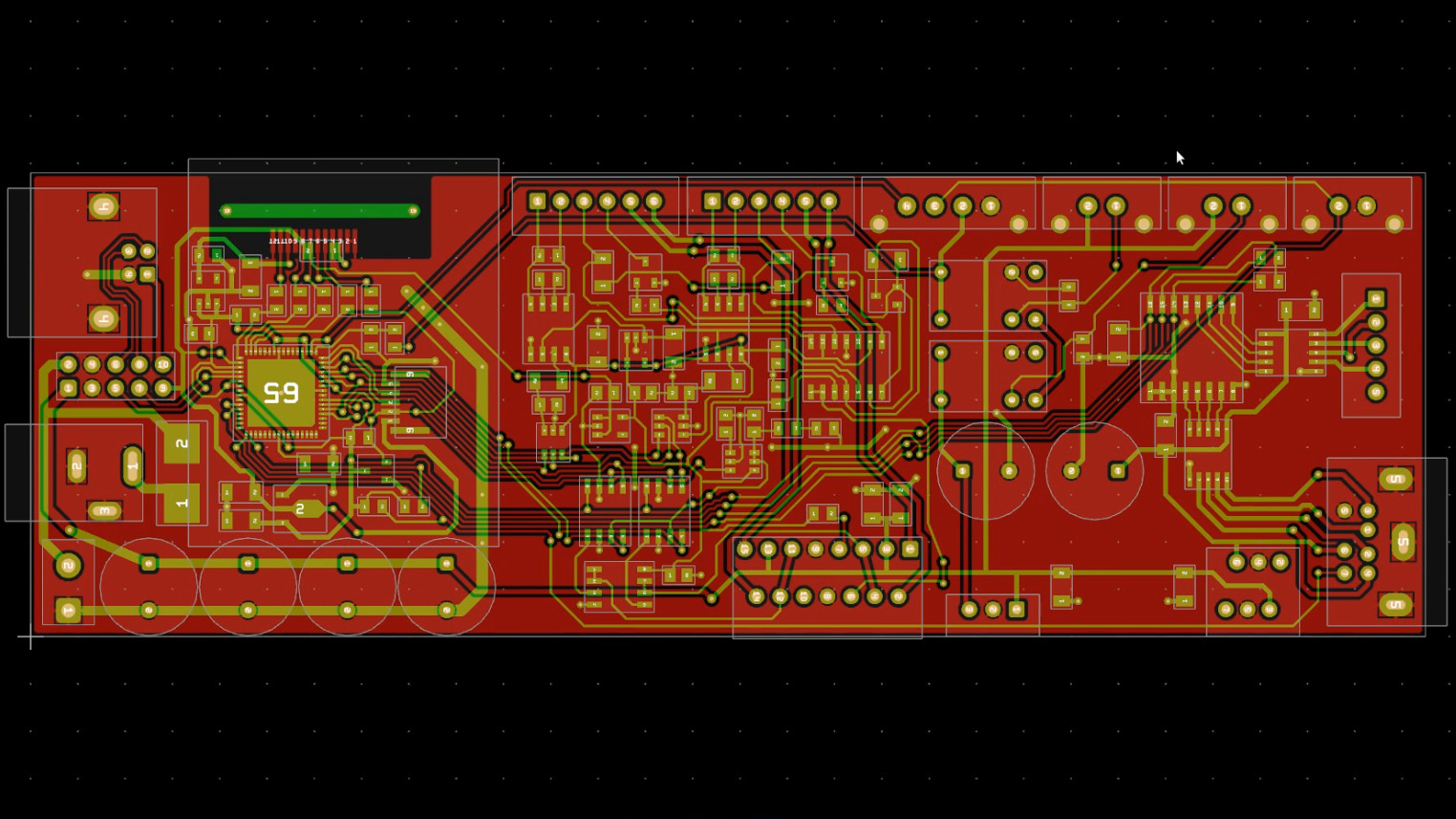

After the specifications for the new product are understood and documented, we get to work on outlining the bill of materials, designing the circuit schematic and the PCB layout along with writing the preliminary firmware and software.

Circuit Prototyping

Following the schematic design, we move towards a functional prototype.

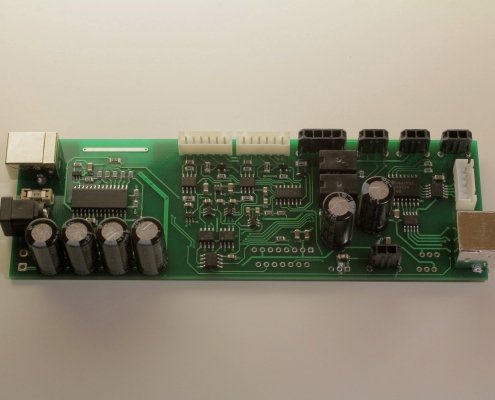

After we have the printed circuit board manufactured, we assemble the and bring up the prototype. This entails assembling all the parts, uploading and refining the firmware to start testing.

Circuit Refinement

After gathering feedback from clients and users, we refine the designs needed. After all the functionality is working as it should including wireless connectivity to the internet through Wi-Fi or cellular, we move onto supporting our clients with any regulatory testing such as FCC, IC, CE RED and EMC.

Next, we deliver all the design files needed to set up a pilot manufacturing as the manufacturing packet.

Also we are there to help and support during and after manufacturing through further version development and optional over the air updates.

Types of electronics we specialize in:

Power systems design

Most electronics systems require a solid understanding of power conversion and handling. The operating conditions within power systems can cover a wide gamut of needed voltages and currents. In particular, the component selection such as MOSFETs, IGBTs, or bipolar transistors are highly dependent on the voltage, and the techniques LAVA LABS uses for developing low-and high-voltage systems are distinctly different and are specialized for the needs of each project.

High-voltage circuits require a lot of experience to design reliably and evaluate safely. At LAVA LABS we design or redesign power circuits and program firmware to improve performance, optimize power consumption, or add new functionality to existing systems.

Our careful choice of components, development tools, and techniques makes our PCB designs compliant with the requirements of FCC, UL, CE, and other necessary certifications for your project.

Battery management system (BMS)

Power conversion system development

Charging system development

Motor controller development

Embedded Systems

As part of our electronics design services, we provide embedded hardware development for a wide range of embedded systems. LAVA LABS works on a variety of chipsets and microcontrollers based on an 8-, 16-, or 32-bit architecture.

Furthermore, we work with ARM-based processors and IoT (Internet of Things) system-on-chips (SoC) from preferred manufacturers such as U-Blox, Texas Instruments, Microchip, and others. We create sophisticated embedded systems with custom firmware for increased security requirements and a rich collection of peripherals and I/O capabilities.

Our embedded system design allows for high- and low-level programming to achieve a variety of desired functionality and control. Whether you are looking for wireless connectivity such as WiFi, Bluetooth, or Cellular, and/or remote control via a phone or web application, our embedded systems can bridge the gap and be very scalable. They can also accommodate battery management systems (BMS) for portable hardware devices.

IOT PRODUCT DEVELOPMENT

- WiFi and Bluetooth

- Verizon IoT Wireless Connectivity

- Verizon ODN and ThingSpace

- Verizon Testing and Certification

- Data Acquisition Systems

- Environmental Sensors

- Processors and Microcontrollers

- LED and Screen Integration

- Embedded Firmware

- AWS IoT Data Architecture

- Alexa Skills and Voice Control

LEARN MORE (IoT Development Page)

REALTIME SENSORS INTEGRATION

- 3D accelerometers and gyroscopes

- Temperature and humidity

- Light | Vision | LiDAR | ToF

- Ultrasonic sound

- Magnetic | Hall effect

- Chemical and gas

AUDIO CIRCUIT DESIGN

- Digital signal processing

- Microphone arrays

- Analog and digital signals

- Bluetooth and WiFi audio

- Audio filtering

- Voice control

POWER SYSTEMS

- Low and High-Voltage Systems

- Top-Efficiency Inverters/Converters

- Advanced Motor Controllers

- Wireless Qi Charging

- Renewables & EV Power Systems

- Rechargeable Lithium-Ion circuits

- Capacity Simulation/Evaluation

- Charge/Temperature Management

- Li-Poly | LFP | LTO | NiMH | NiCd

LEARN MORE (Power Systems Page)

CUSTOM CIRCUIT AND PCB DESIGN

- Circuit prototyping and testing

- FCC, UL, RoHS, CE certification

- Hardware product development

- FPGA design and testing

FIRMWARE + SOFTWARE

- Web apps for realtime data

- Hardware control via apps

- SaaS software development

- Firmware and drivers

- Point of contact for IoT

- AWS | Lambda | IoT Core

- Mobile iOS and Android